Introduction of on-line roll profile measuring of roll grinder

The steel industry has increasingly higher requirements for the accuracy and production efficiency of roll grinders, so it has put forward higher requirements for the design, manufacturing, inspection and other aspects of roll grinding machine. Among of, roll accuracy inspection is important to ensure product quality. therefor, online roll profile measurement has emerged along with the requirements of automation development. At present, there are mainly single-probe measurement and double-probe measurement, of which double-point measurement is more used.

Double probe measuring can be divided into two types according to the installation method:

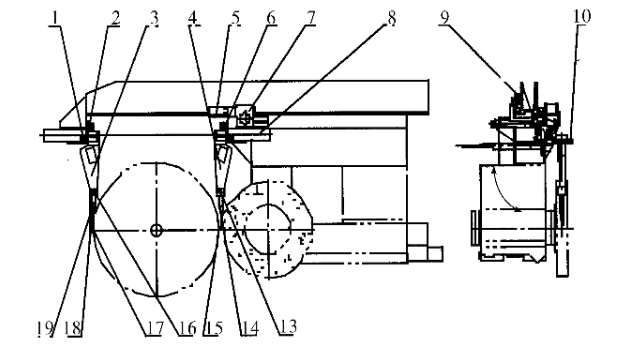

1) Measuring device mounted on grinding wheel stand (as Figure 1)

Figure 1

This type of measuring device consists of measuring beam, moving mechansim, internal and external measuring probe, etc. The two inner probe is fixed on the grinding wheel stand, and the outer measuring probe is installed on the beam. There is a moving mechanism to drive the measurement to move in straight line.

This type of measuring device can measure the roll profile, roll diameter, cylindricity, roundness and coaxiality, and can also measure the installation accuracy of the roll. Measurements can be performed before and after grinding. The measurement data can be incorporated into the CNC grinding process. Comparing with the roll grinding accuracy, allow the CNC roll grinder to automatically perform or interrupt the grinding cycle and compensate for grinding.

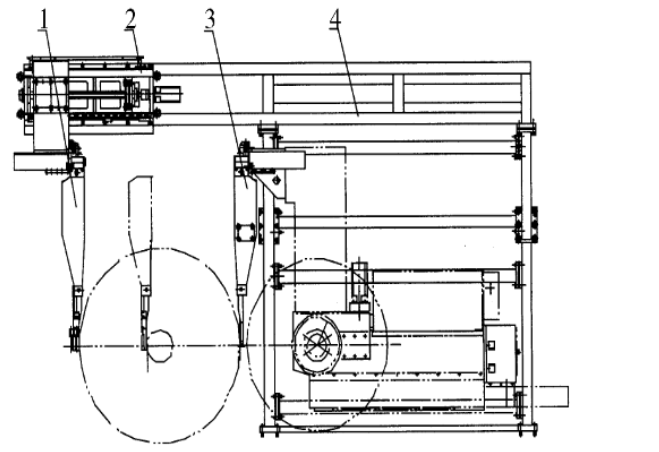

2) Measuring device installed on carriage

This type of measuring device mainly consists of a measuring base, a 90° rotating mechanism, a 30° rotating mechanism, a measuring moving mechanism, inner measuring probe, and outer measuring probe.

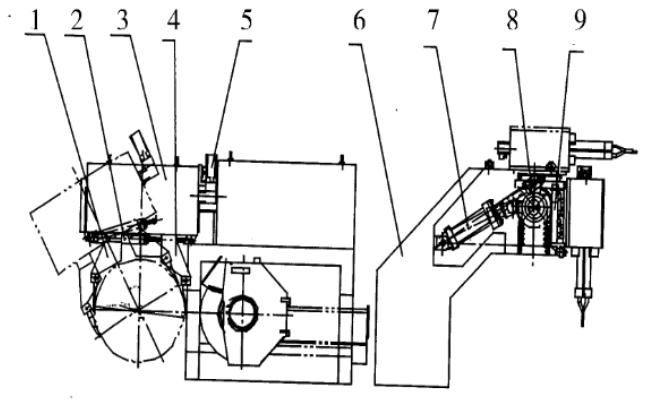

The measuring device installed on the carriage has two measuring positions, one is horizontal measurement (as shown in Figure 2). For the other type, the 30° rotation mechanism is driven the oil cylinder to rotate 30° around the center of the workpiece, which can be measured while grinding (as shown in Figure 3).

Figure 2

Figure 3

To make a summary of above measuring device of CNC roll grinding machine. For figure 1, it can reduce roll grinder length, but cannot get good grinding effect while grinding wheel move slowly, and cannot do measuring while grinding. Figure 2 structure can save space and grinding wheel do not need to bear extra weight of measuring beam, but it also cannot realize measuring and grinding at same. Figure 3, the measuring probe can rotate for a certain angle, so can realize measuring and grinding at same.