Rubber roll

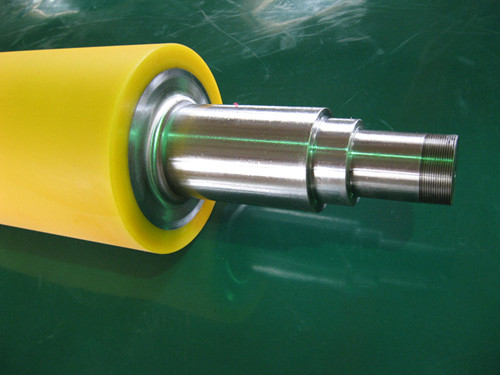

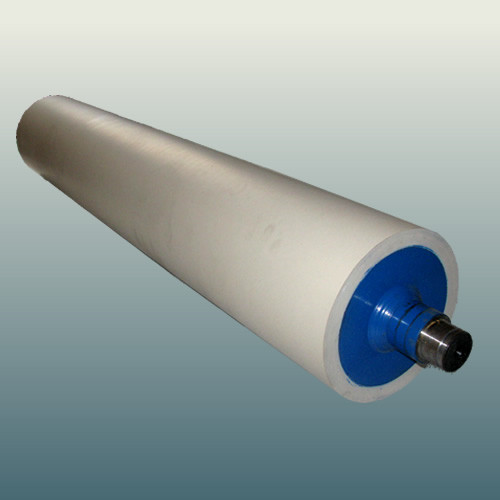

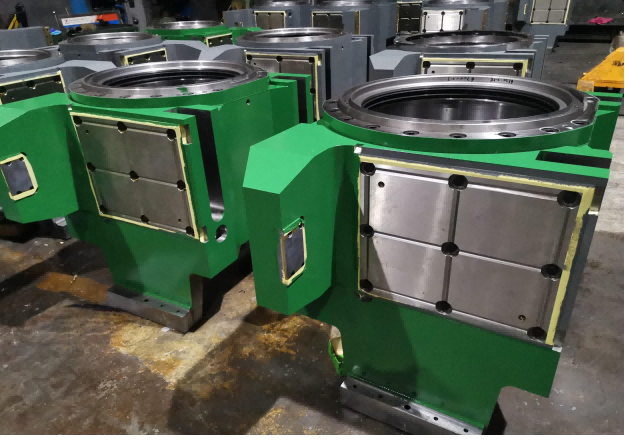

Rubber roll are generally composed of outer layer of rubber, hard rubber layer, metal core, roll neck and vents. Their processing includes roll core sandblasting, bonding treatment, rubber forming, cloth wrapping, wire winding, autoclave vulcanization and surface processing etc. The rubber rolls are mainly used in papermaking, dyeing, printing, grain processing, metallurgy, plastic processing, etc.

Our company provides rubber rolls of various specifications with various materials which can be used for steel, non-ferrous metal processing, papermaking, textile, dyeing and printing industries, such as press roll, turning roll, steering roll, squeezer roll, pickling roll, immersion roll, sinking roll, sealing roll, color coating roll, support roll, tensioning roll, wring roll etc.

The materials of rubber roll; polyurethane, nitrile, chloroprene, EPDM, chlorosulfonated polyethylene, silicon, fluorine, etc. We can meet the needs of various uses and production conditions.

Rubber rollers specifications:

Length: 100~5000 (mm)

Diameter: Φ50~Φ1500 (mm)

Hardness Shore A 10~97

Shore W is commonly known as "0" degree.

Special specifications and uses roll can be designed and manufactured according to user requirements.