Seven Roller Straightening Machine

Seven Roll Straightening Machine/seven roll straightener is used to straighten the bending of bar or tube created in the rolling process. This metal straightening machine has obvious effect in solving bar head or tail bending, eliminating slight ellipticity and removing oxide scale.

Producing material of seven roll straightener include carbon tool steel, carbon structural steel, alloy tool steel, alloy structural steel, spring steel, stainless steel, bearing steel, titanium chromium nickel alloy etc.

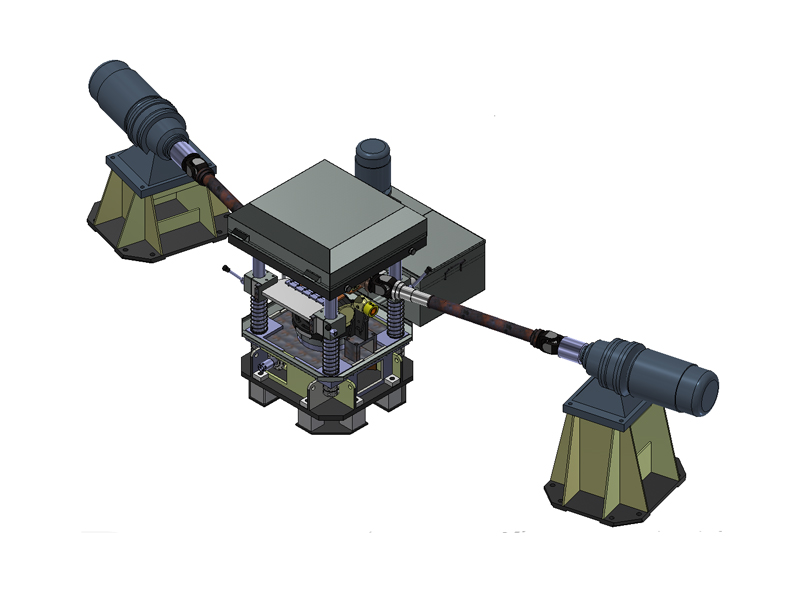

Structure of seven roll straightening machine/ seven roll straightener: 2 beam 5 column, and seven oblique roller (2221) structured. Two pairs of rollers are powered ones with upper roller equipped with powered pressing down mechanism. Both up and down roller are equipped with angle adjusting mechanism, and the middle bottom roll is installed with manual lifting adjustment mechanism.

Principle of seven roll straightening machine/ seven roll straightener: adopts crossed and symmetric pressing straightening principle. Through the inclined arrangement of roller, the design of roller shape, distance between rollers, and the matches of guiding distance, the bar experiences multiple times of crossed symmetric pressing, This metal straightening machine makes each section of bar subjected to multiple elastic-plastic bending deformation, and eventually acquires higher straightening precision.

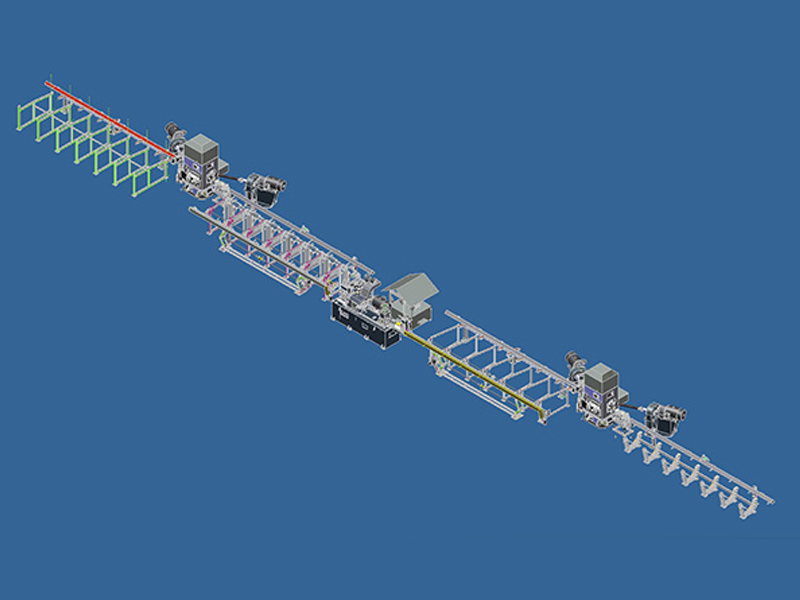

The seven roll straightening machine/seven roll straightener is composed of loading system, straightening main body, unloading or discharging table roller and discharging collective system, with corresponding electronic control, equipment lubrication and cooling system.

Straightness after fine straightening: ≤1‰.

Note: above picture and parameter are only for reference, please contact for detail of straightening machine.