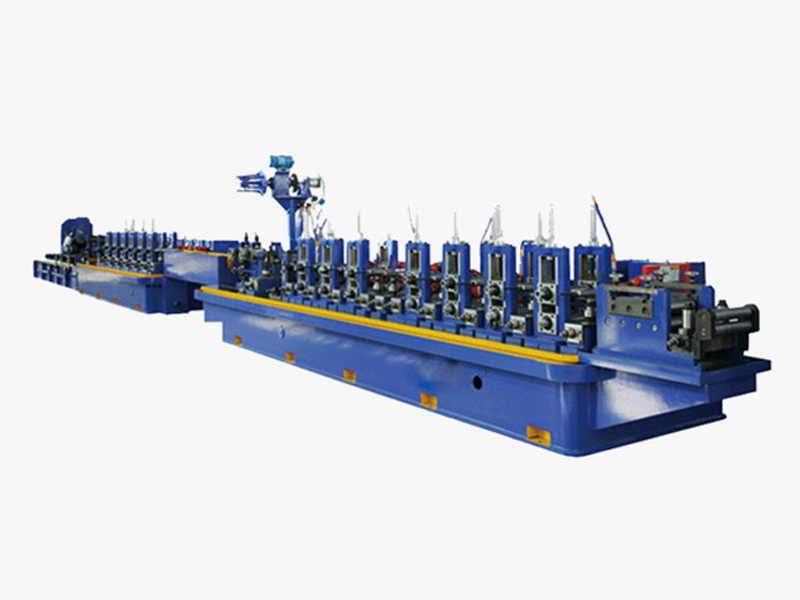

ERW Tube Mill

ERW tube mill/pipe mill/tube making machine/pipe making machine/tube forming machine/pipe forming machine is as known of steel tube manufacturing line, using the high frequency welder and rollers to produce all kinds of steel tube, profile, etc.

The steel tube production line has the advantage of high production efficiency, high automatization, high yielding (work stable at high speed), low production cost, saving roller changing time, roller saving and high accuracy.

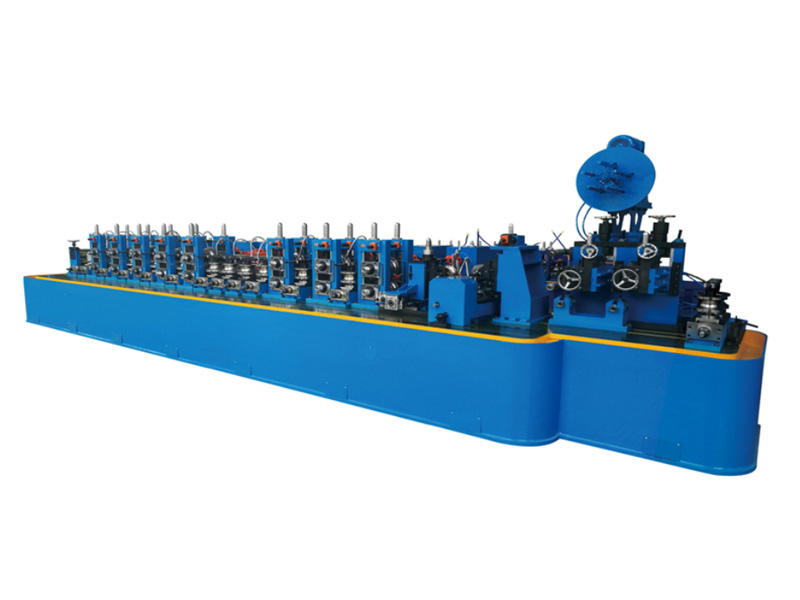

Application of the ERW T tube mill/pipe mill/tube making machine/pipe making machine/tube forming machine/pipe forming machine: construction tubes, precision tubes, auto tubes, fence, heat exchanger, furniture tube, pressure tube production, with suitable finishing equipment, machine also can be capable to produce the API pipe, gas transportation, and high standard tubes and so on.

Material: GI, Carbon steel, stainless steel tubes

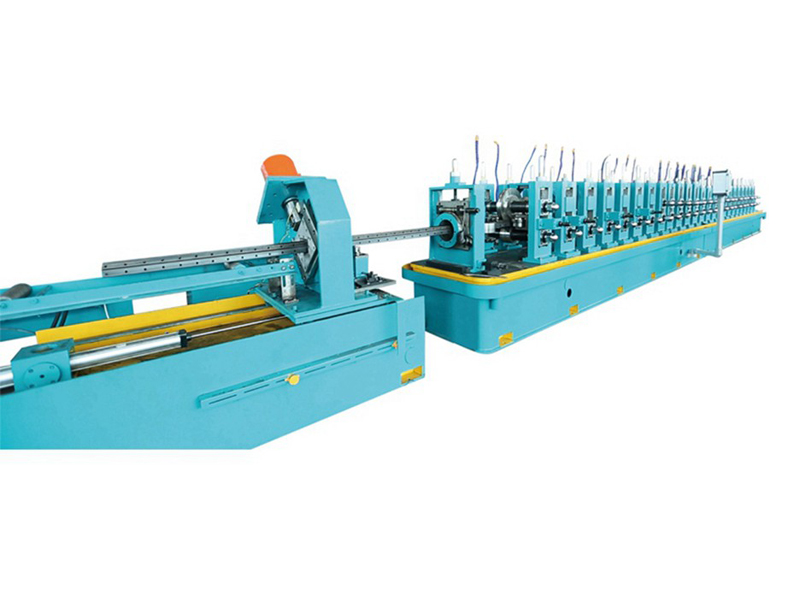

Production process of ERW Tube Mill/pipe mill/tube making machine/pipe making machine/pipe forming machine/tube forming machine: Scrolling up→ Uncoiler→ Shear & welding machine→ Accumulator→ Forming machine→ HF welding→ External burr removing→ cooling → Sizing→ Flying saw (Cold saw) → Run out table→ inspecting→ packing→ warehouse.

Above process are for reference, it will be designed based different requirement of client.

Reference parameter for machine choose:

Round pipe: Ф8-20mm to Ф355-720mm

Square pipe: 6*6mm to 600*600mm

Thinckness: 0.3-22mm

Note: above pictures and parameters are only for reference, please contact for detail of tube mill.