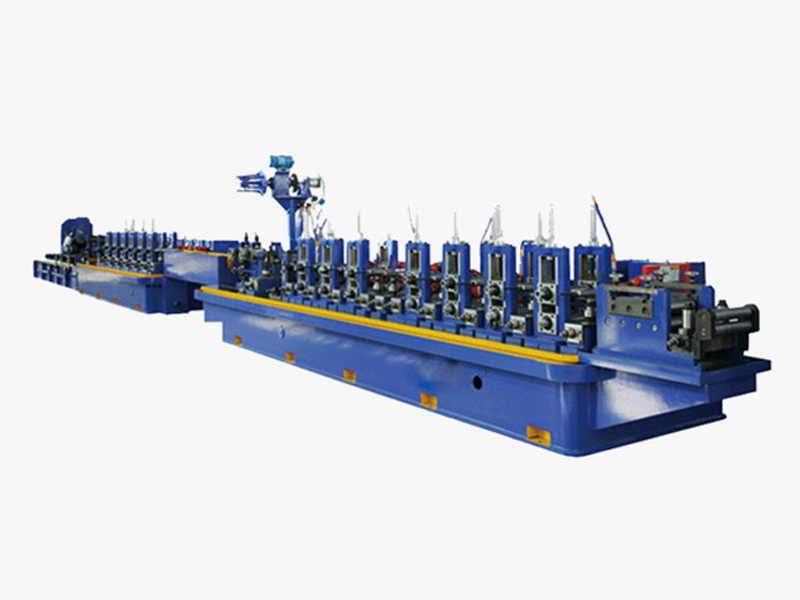

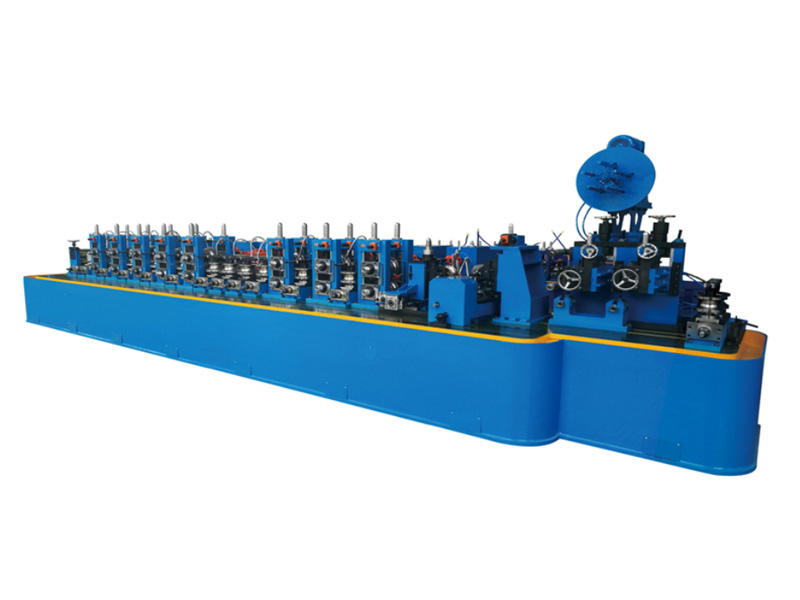

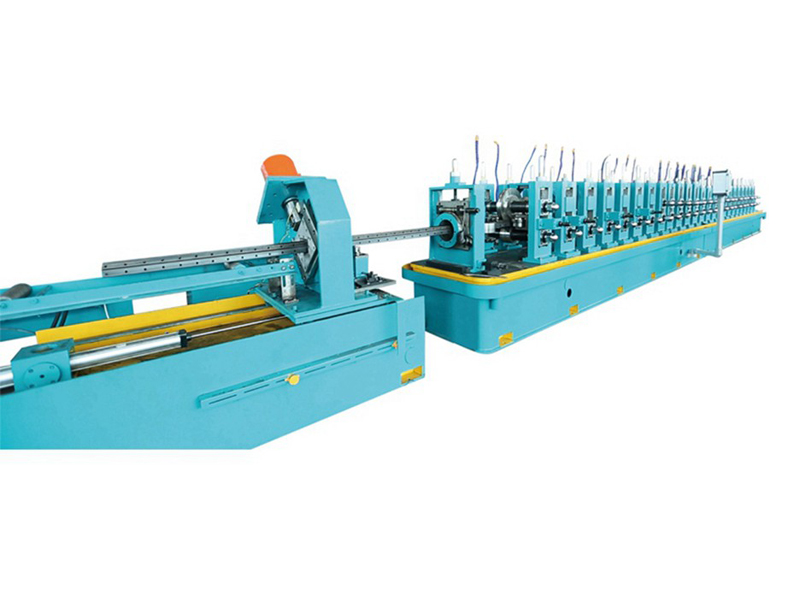

Square Tube Mill

Square to square tube mill/ square pipe making machine is as known of square tube manufacturing line which is directly roll the steel strip and bend it to square & rectangular shapes, then weld it to finish the formation.

Advantage of square pipe mill:

1.It is better for shape at the edge of cross section, semi-diameter of inner arc is comparatively small and the brim is flat and outlook is regular.

2.Low load and especially the sizing parts.

3.The width of steel strip is small and save raw material.

4.Adapting multi-point bending, avoid axial force and side abrasion, thus reduce forming step and ensure quality.

5.Power and roller abrasion reducing.

Material: GI, Carbon steel, stainless steel tubes

Application of the tube mill/pipe mill/tube making machine/pipe making machine/pipe forming machine/tube forming machine: construction tubes, precision tubes, auto tubes, fence, heat exchanger, furniture tube, pressure tube production, with suitable finishing equipment, machine also can capable to produce the API pipe, gas transportation, and high standard tubes and so on.

Production process of tube Mill/pipe mill/tube making machine/pipe making machine/pipe forming machine/tube forming machine: Uncoiler→ Shear & welding machine→ Accumulator→ Forming machine→ HF welding→ cooling → Sizing→ saw → Run out table→ inspecting→ packing→ warehouse

Above process are for reference, it will be designed based different requirement of client.

Reference parameter for square pipe making machine:

Square pipe size:60*60-150*150mm ~200*200-500*500mm

Rectangular pipe size: 70*50-200*100mm~250*150-600*400mm

Thcikness: 1.5-8mm~4-20mm

Speed: 8-70m/min

Note: above pictures and parameters are only for reference, please contact for detail of tube mill.