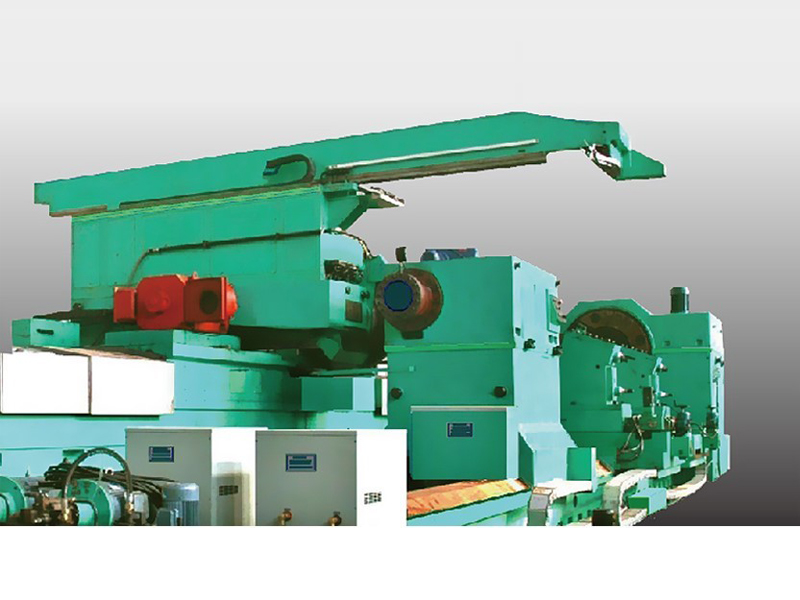

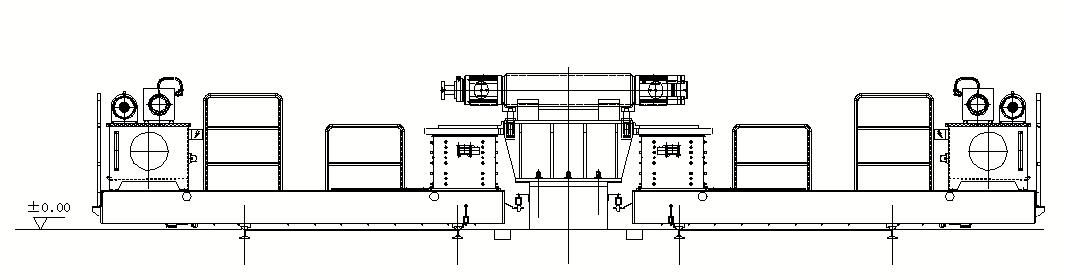

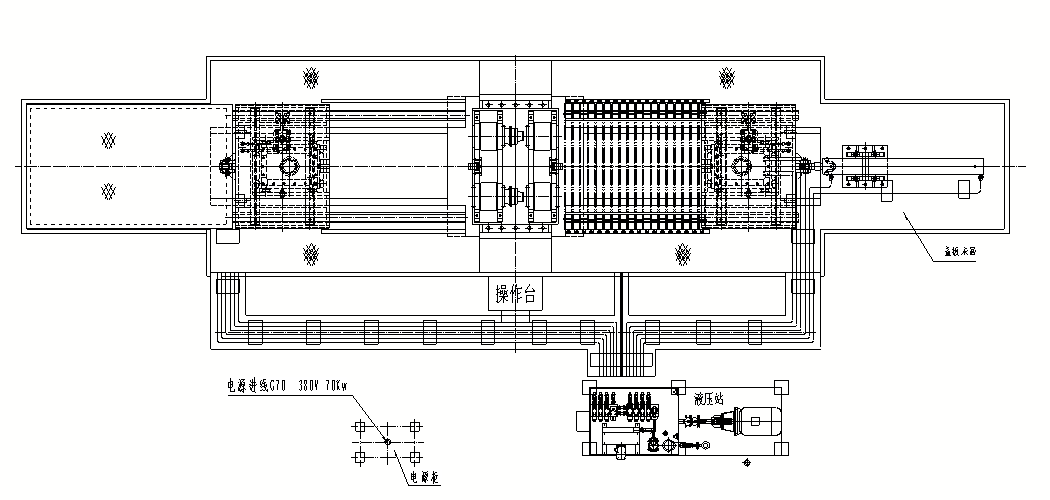

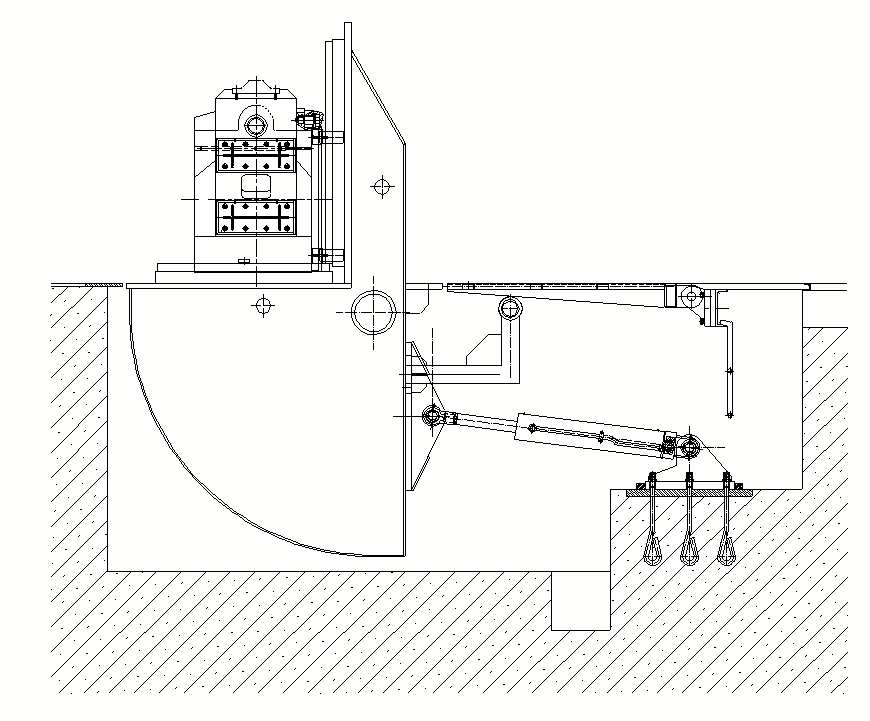

CNC Roll Grinding Machine

CNC roll grinder is suitable for high-precision and high surface quality grinding of work roll, intermediate roll, back up roll on rolling mills in the non-ferrous and metallurgical industries, various pressure rolls in the rubber industry and various metal and non-metal pressure rolls in printing and dyeing industry.

The roll grinder realize the grinding of cylindrical roll surface, convex and concave curve, CVC curve, arbitrary curve and other user-defined grinding.

We have four type of roll grinder to meet various requirement of industry:

Roll grinder with grinding wheel traveling, which is widely used to grind metal & non-metal roll for steel industry, non-ferrous industry, paper industry, roll manufacturing and other industry, and can realize the grinding of cylindrical roll surface, convex and concave curve, CVC curve, arbitrary curve and other user-defined grinding.

Roll grinding machine with workpiece movement is special designed and produced for grinding slender roll & shaft, such as work roll, intermediate roll and support roll for multi-roller rolling mill in steel or copper strip production, aluminium foil production etc.

Roll grinder specialized for hot rolling production. Beyond of high precision, stable performance and high degree of automation, it can grind roll with bear box which minimize the damage caused by frequent disassembling, highly reduce labor intensity and maintaining cost, and highly improves production efficiency.

Economic and light duty CNC roll grinder is especially suitable for the grinding of drying cylinder, pressure roll, metal or non-metal roll in paper industry. Besides, it is also used the work roll and back up roll grinding for steel industry, copper industry, and aluminium foil industries.

Feature:

Roll grinder adopts a large number of advance SIEMENS control technology and mechanical transmission technology, with independently developed control software

Roll grinding machine equips Siemens digital controlled AC servo motor with high precesion, less maintaining and high performance

The measurement sytem of roll grinder use Germany Heidenhain linear grating to ensure roll meansuring precison and roll position precision of CNC roll grinding machine.

Lismar & domenstic made eddy current testing system are option

The CNC roll grinder has the characteristics of high efficiency, high precision, powerful function, high degree of automation, safe and reliable use, as well as timely remot data trasmission. The CNC roll grinder can connect to roll shop management system of workshop.

Specification of CNC Roll Grinding Machine

Min. roll diameter: 30mm

Max. roll diameter: 2500mm

Max roll weight: 250T

Grinding wheel linear speed: 45m/s