Skin Pass Mill

The skin pass mill is a device used for post-processing of cold-rolled strip. It can improve the flatness of the cold-rolled strip and also can improve the mechanical properties of the cold-rolled strip, such as deep drawing performance.

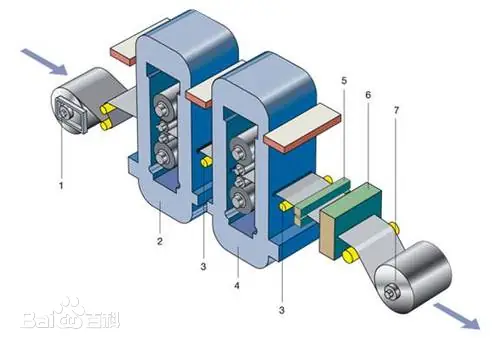

The skin pass mill is mainly composed of the leveling machine, main transmission device, roll changing device, etc. The maind body of skin pass consists of frame, upper and lower working rolls, upper and lower support rolls, pressing head device, bending roll cylinder, balancing cylinder, pressing cylinder, etc.

The process flow of skin pass mill

Uncoiler----Hydraulic shear----entry roller“S”----entry anti-crinkle rollers--- four/two rollers----lever unit---entry anti-crinkle rollers----exit roller“S”---Coiler

Features of skin pass roll

Two-roller and four-roller are for choose. The four-roller skin-pass mill series is equipped with hydraulic AGC pressing system and automatic adjustment device.

"S" rollers, anti-crinkle rollers, and anti-jump rollers are installed in front and behind the machine, with automatic belt threading function and easy operation.

Fully automation with computer online control, with function of parameter pre-setting detection, display, alarm, storage record and query of process parameters and key equipment parameters

Producing range of skin pass

Strip thickness:0.3-1.0mm~0.2-0.8mm

Strip width:50mm-300mm ~1000-1200